How Our Hybrids Work

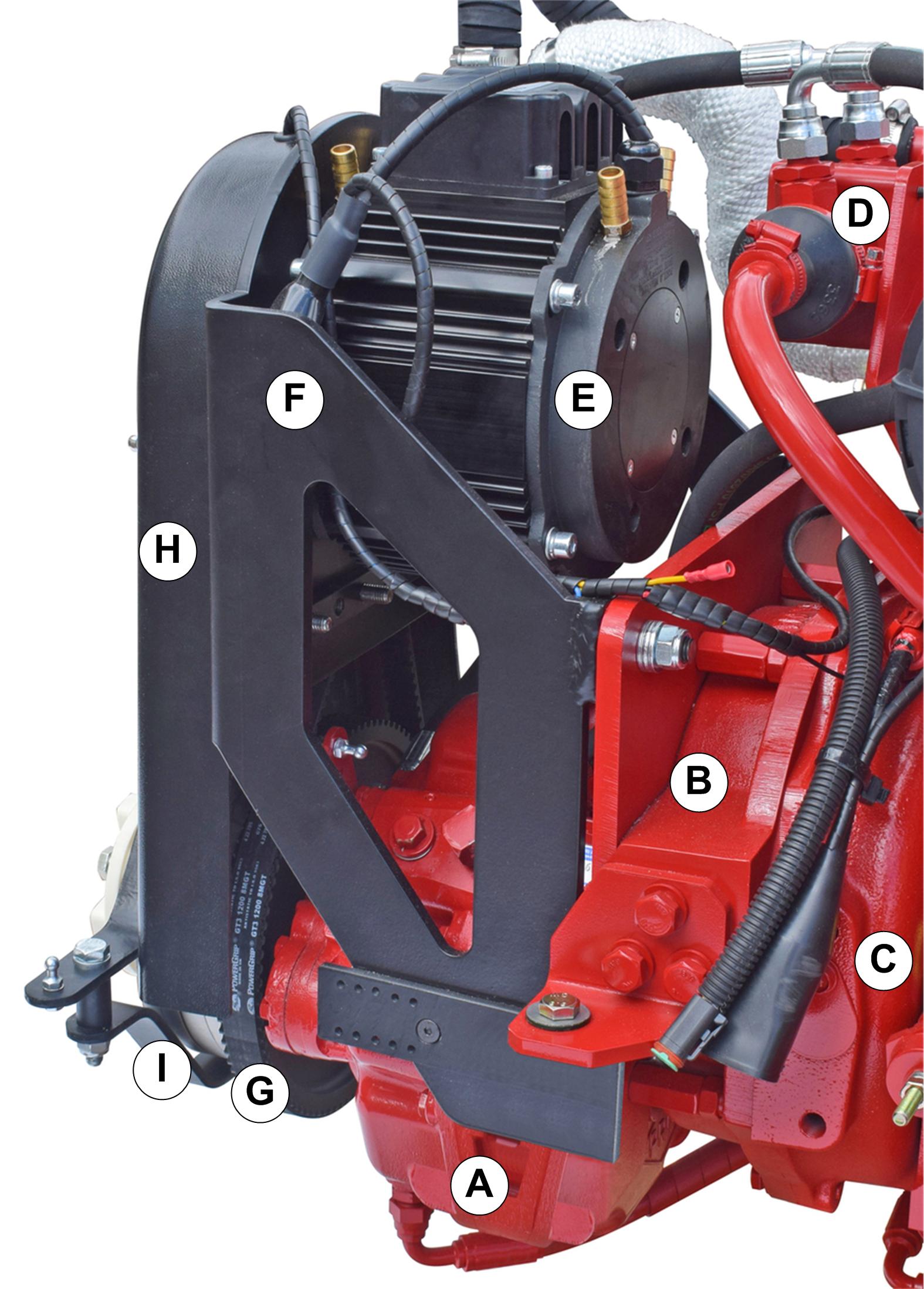

The image below shows the business end of a single motor hybrid. Start by looking at the component parts

|

System Overview

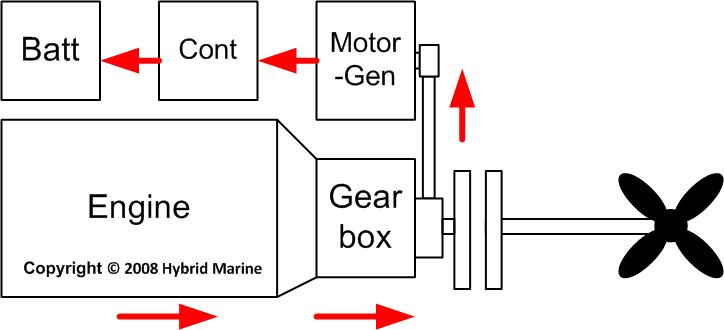

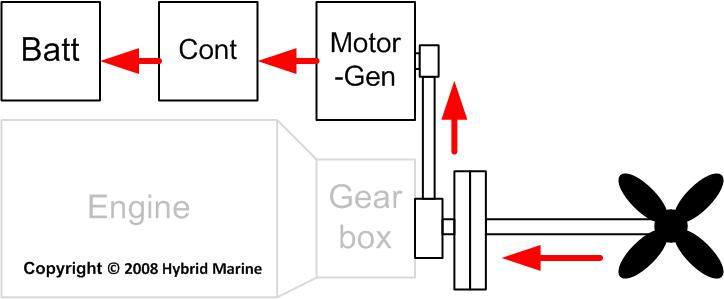

Below is a simplified diagram of the main hybrid components.

Basic operation

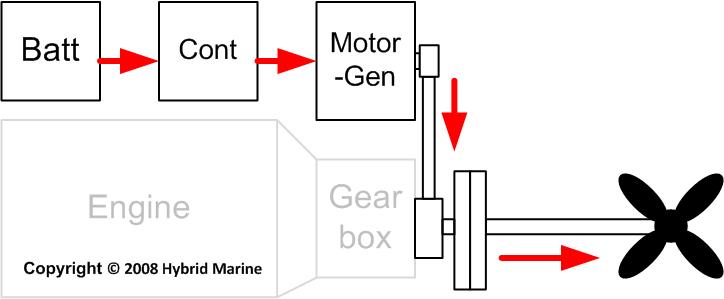

With the engine turned off and the gearbox in neutral, the electric motor can drive the propeller using energy from the battery bank. Speed and direction are set by the controller.

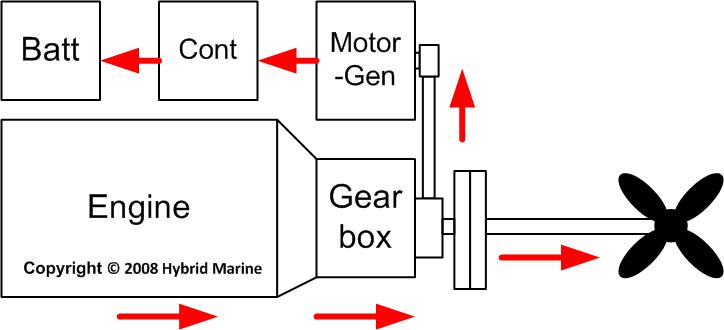

When the batteries run down, (or high propulsion power is required), the engine is started and the gearbox put into drive. At this time, the controller senses the engine is running and switches the motor to generate mode. So the engine now drives the propeller, and the motor acts as a generator to recharge the batteries.

When the batteries are recharged, you can stop the engine. The controller senses the engine has stopped and automatically switches back to electric drive mode.

The engine does not need to run all the time, and when it is on, it is substantially loaded by the propeller + generator. The engine running at higher loads gives us greater efficiency; see Hybrid Efficiency section.

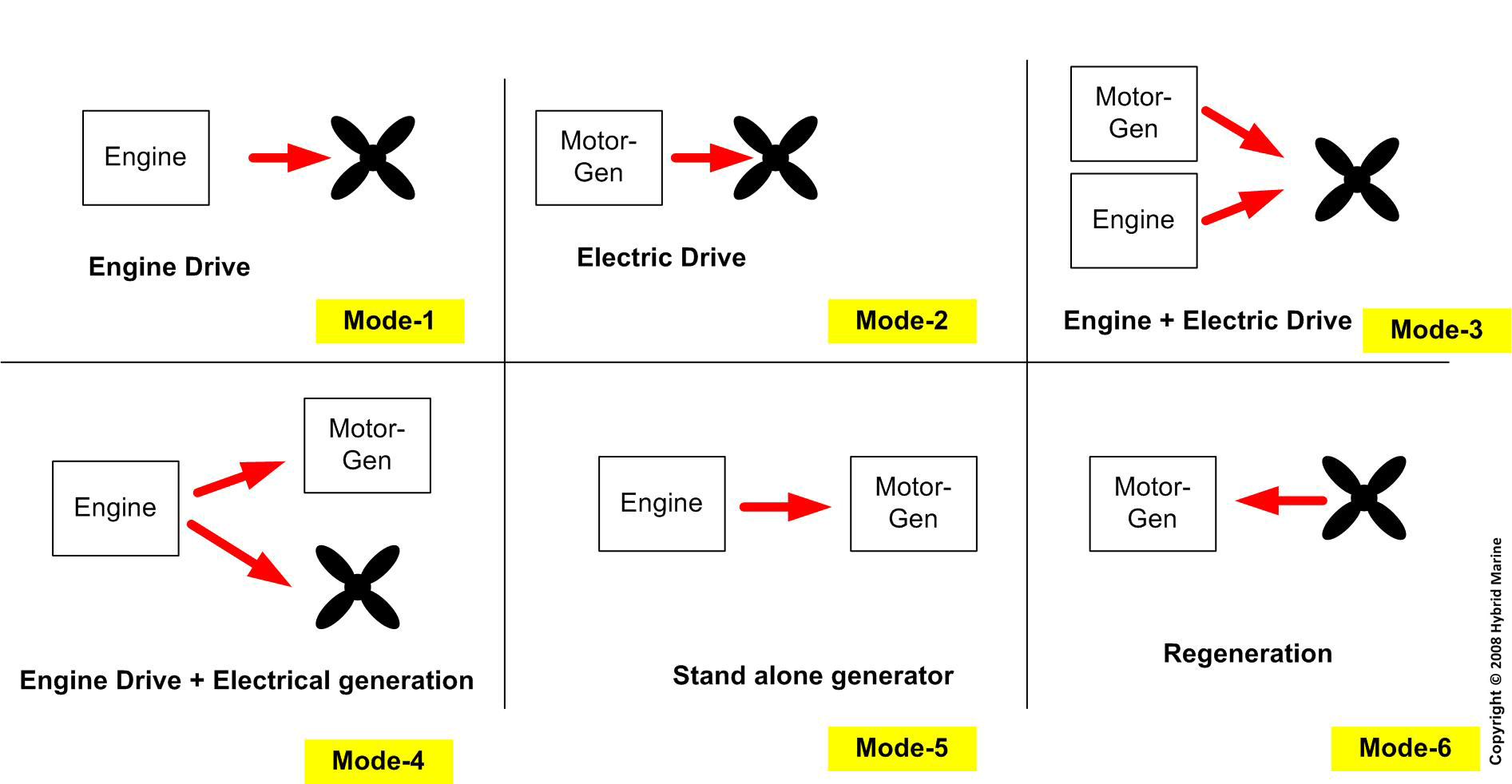

The six operating modes of a Hybrid

There are six basic operating modes for a hybrid (sometimes referred to as power flows), these are:

How the Hybrid Marine System provides the six modes of operation

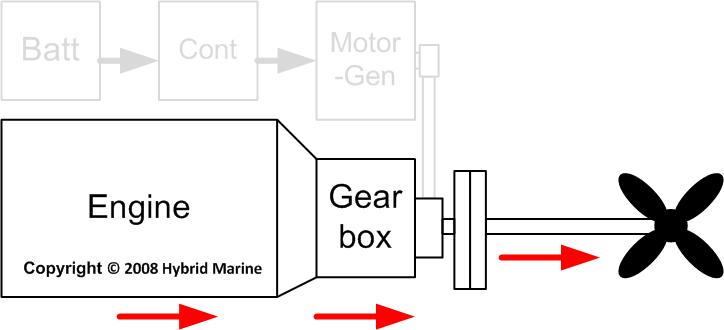

Mode 1 – Engine drive |

Mode 2 – Electric drive |

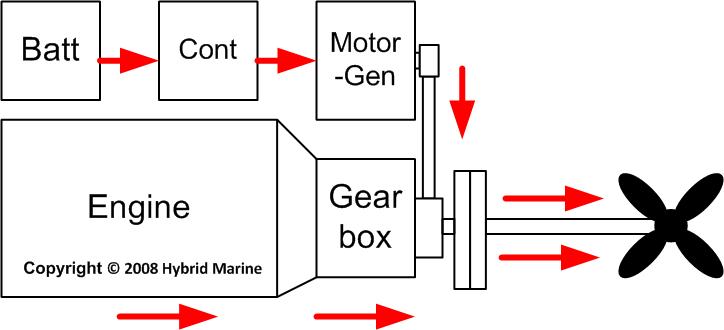

Mode 3 – Engine + electric drive (boost mode)

Both the engine and electric motor drive the propeller. This is used to good effect in automotive applications but has limited advantage for a marine hybrid. For automotive applications, the maximum power requirements are during acceleration. Once a car has achieved cruising speed, the power required drops off. Having a motor boost the engine for short periods of acceleration means you can downsize the engine. A marine application is quite different. Power demand is constant and determined by a vessel's speed. Acceleration is not so relevant unless it is a fast planning craft. Therefore, a motor boost must be present for much longer periods to be effective. Battery banks would need to be large to provide sufficient energy for a prolonged boost and would then add extra weight (requiring more propulsion power). You would need to set the propeller to absorb the power of the motor plus the engine. When your batteries eventually run down, you are back to the engine only. However, now your propeller is too big and overloading the engine when it does not have a motor boost. Although motor boost is theoretically possible, we do not implement it in most of our applications. General advice is to size the engine for maximum power requirements and to have the motor/generator in generating mode whenever the engine is running. |

Mode 4 – Engine drive and electrical generation |

Mode 5 – Stand-alone generator |

Mode 6 – Regeneration |