Hybrid Efficiency

It is a common assumption that hybrids are efficient and will save on fuel. A well-designed system in the right application can provide considerable fuel savings. However, a poor hybrid design, in an inappropriate application, can use far more fuel than the conventional system it has replaced. In this section, we will look at some of the fundamentals to gain a better understanding.

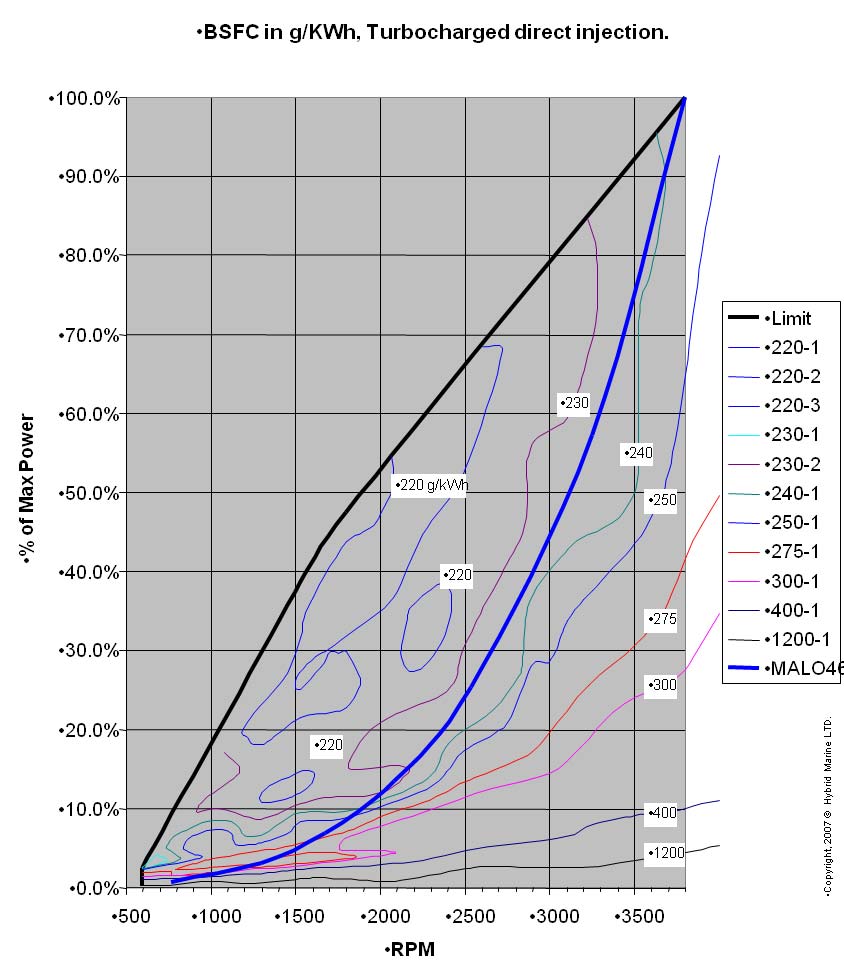

Let's start by looking at the performance of a conventional Diesel engine. The first thing to consider is that when an efficiency is quoted then this is only at one specific operating speed and load. Generally, this is stated at the best-case operating point of the machine. However, efficiency varies a great deal over speed and load.

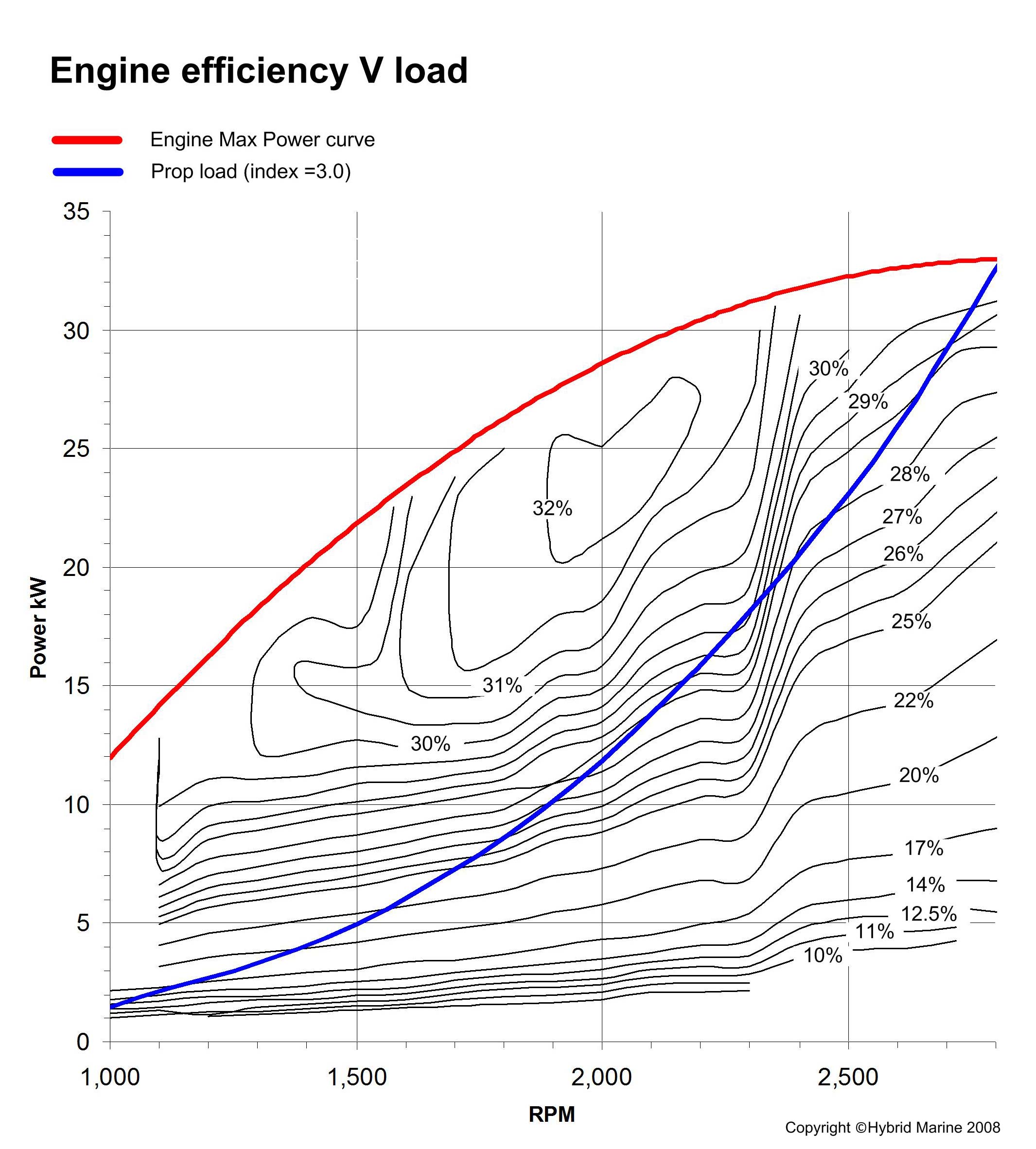

The graph shows Speed against Load for a typical 30Kw/43Hp industrial diesel engine & gearbox marinised for marine use (more about this later). The red line is the maximum power the engine can deliver to the drive shaft over its speed range. This is normally termed the net intermittent rating, that is it can not maintain this power indefinitely (one hour only). The blue line is a typical load the propeller applies to the prop shaft over the speed range of the engine. If the propeller is selected correctly then it allows the engine to reach its maximum rated speed and fully loads it at this point.

One Litre of diesel fuel contains 10kWh of heat energy. That is, if you burn the fuel in a diesel heater, it would give off this amount of heat energy, equivalent to a 2kW fan heater running for 5 hours. The engine/gearbox converts this heat energy to useful mechanical energy at the drive shaft. The Diesel is a fairly inefficient machine, and in this case, the best it can achieve is about 32%. That is, 32% of the energy in the fuel ends up as useful drive at the prop shaft, and 68% is lost as heat in the cooling and exhaust system.

The contours on the graph show the engine's efficiency at any possible load & speed. The blue line is the actual load applied to the engine across its speed range. The first thing to note is that the contour of maximum efficiency is 32%; this is achieved at a load of around 23kW and speeds of around 2,000. The propeller load comes nowhere near this area of operation, and the engine never works at its maximum possible efficiency. At maximum speed, the engine achieves 30% efficiency. As the speed reduces so does the propeller load, at low engine RPM the load on the engine is very small and efficiency dips below 10%. At this point, 90% of the energy in the fuel consumed is lost as heat. If the engine is idling in neutral (no load), then efficiency is zero, as no useful drive is achieved.

If we can operate the engine with better efficiency using a hybrid, then improvements in fuel economy can be achieved. All hybrid uses the principle of energy buffering; how this is achieved depends on the type of hybrid, but the basics are the same. Looking back at the graph, the engine can operate at any speed between 1,000RPM and 2,800RPM. at lower speeds, the prop load is small, and deficiency is low. If we add an extra load to the engine above the prop load, then we can make it work harder. As can be seen from the graph, at higher loads, the efficiency improves. As an example, let us consider the following two cases :

The engine is operating at 1,200 RPM (typical canal boat case). Propeller load is low at about 3kW, and efficiency is low at around 15%. If we add an extra load of 8kW to the engine, with an electrical generator, then the total load would be 11kW. At 1,200 RPM and a load of 11kW, the efficiency almost doubles to 30%. So, working the engine harder than is required by the prop load improves efficiency. The extra energy extracted by the generator is buffered in a battery bank and can drive the craft through an electric motor with the engine stopped. The engine does not need to be on all the time, and when it is running, it is operating with better efficiency. There are, of course, losses involved in extracting this energy, buffering it in the battery bank and returning it to the drive chain (see What is a Hybrid? for examples of typical losses encountered). If the improvement in engine efficiency outweighs these extra hybrid losses, then overall fuel savings are archived. This is by no means a given.

The second case to consider is the engine running at near full speed and load, let us say, 2,500 RPM and a prop load of 23kW. Here, the engine deficiency is around 28%. We could add an extra load to the engine and improve this by a few percent. However, the losses involved in extracting, buffering and returning to the drive chain would far outweigh any small efficiency in engine operation achieved.

A better engine

|

Conclusion

From this discussion, the case for a Hybrid depends a good deal on the type of craft, type of engine and how it is used. If you have a powerful boat that you like to run at speed, the engines are well-loaded, and a hybrid can not offer any absolution here. Engines are normally sized to deal with worst case conditions, if then operated at low loads for a substantial periods, then a hybrid can provide improvements in fuel economy. If a vessel experiences long periods of engine idle and has regular access to charging points, then a hybrid can work effectively here.

Hybrids add extra components and costs to an installation. This needs to be weighed against improvements made in operating efficiency. There are many other benefits to consider apart from fuel savings. Once you have a hybrid, then further improvements in fuel economy can be made as follows :

- Engine idling can be eliminated. Hybrid motors can be brought into use instantly and consume no power when stationary.

- Opportune shore charging can replenish the battery bank, reducing fuel used.

- Other sources, such as wind or solar, can charge the battery bank and contribute to the power budget.

- On sailing craft, energy can be regenerated from a free-wheeling propeller.