Which Hybrid is Best?

This is not a simple question; sometimes, the answer is to stay with a conventional engine (see Hybrid Efficiency).

Before considering this question, make sure you have read What is a Hybrid? and Hybrid Efficiency sections.

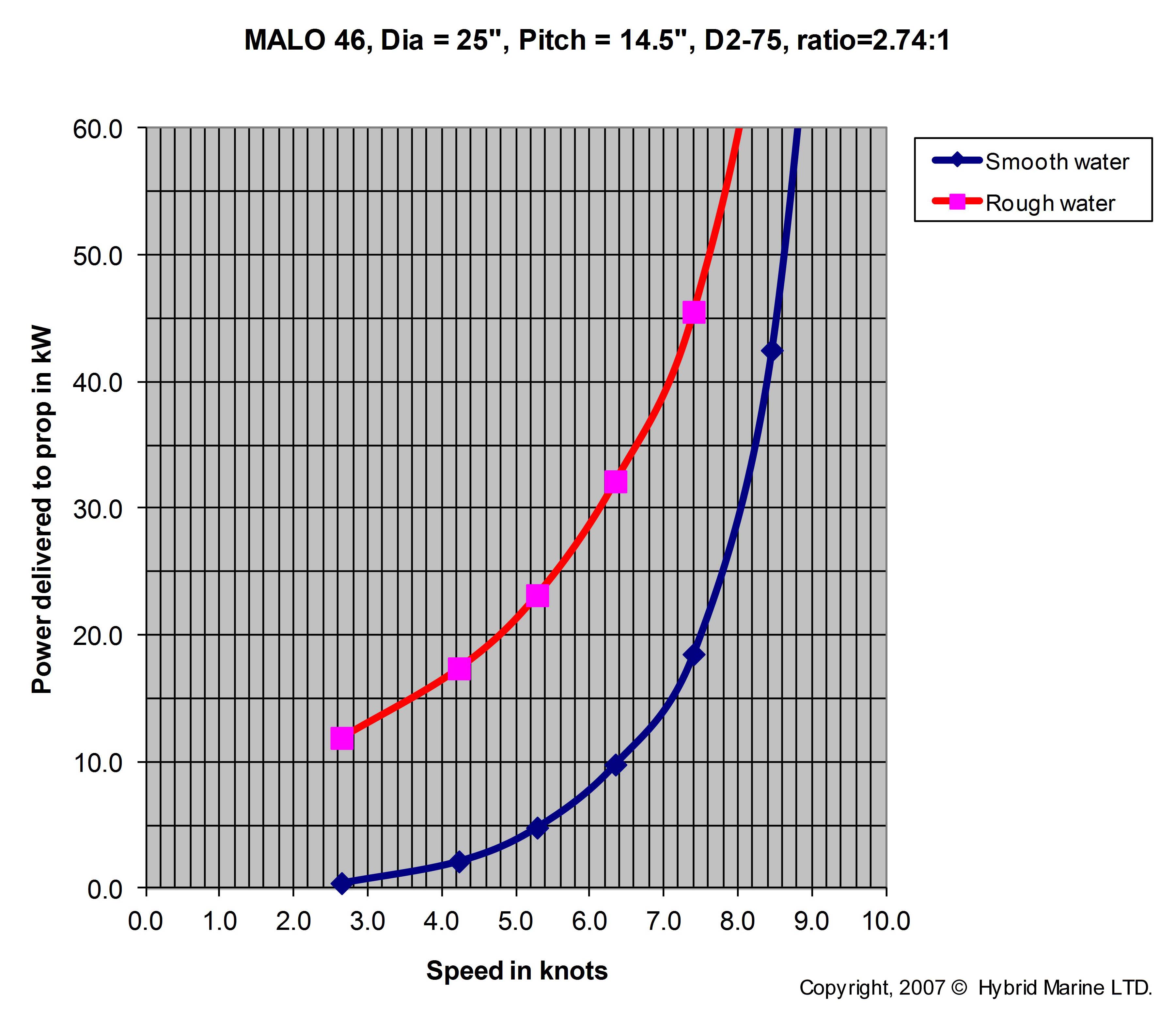

What does it take to power a marine vessel? |

|

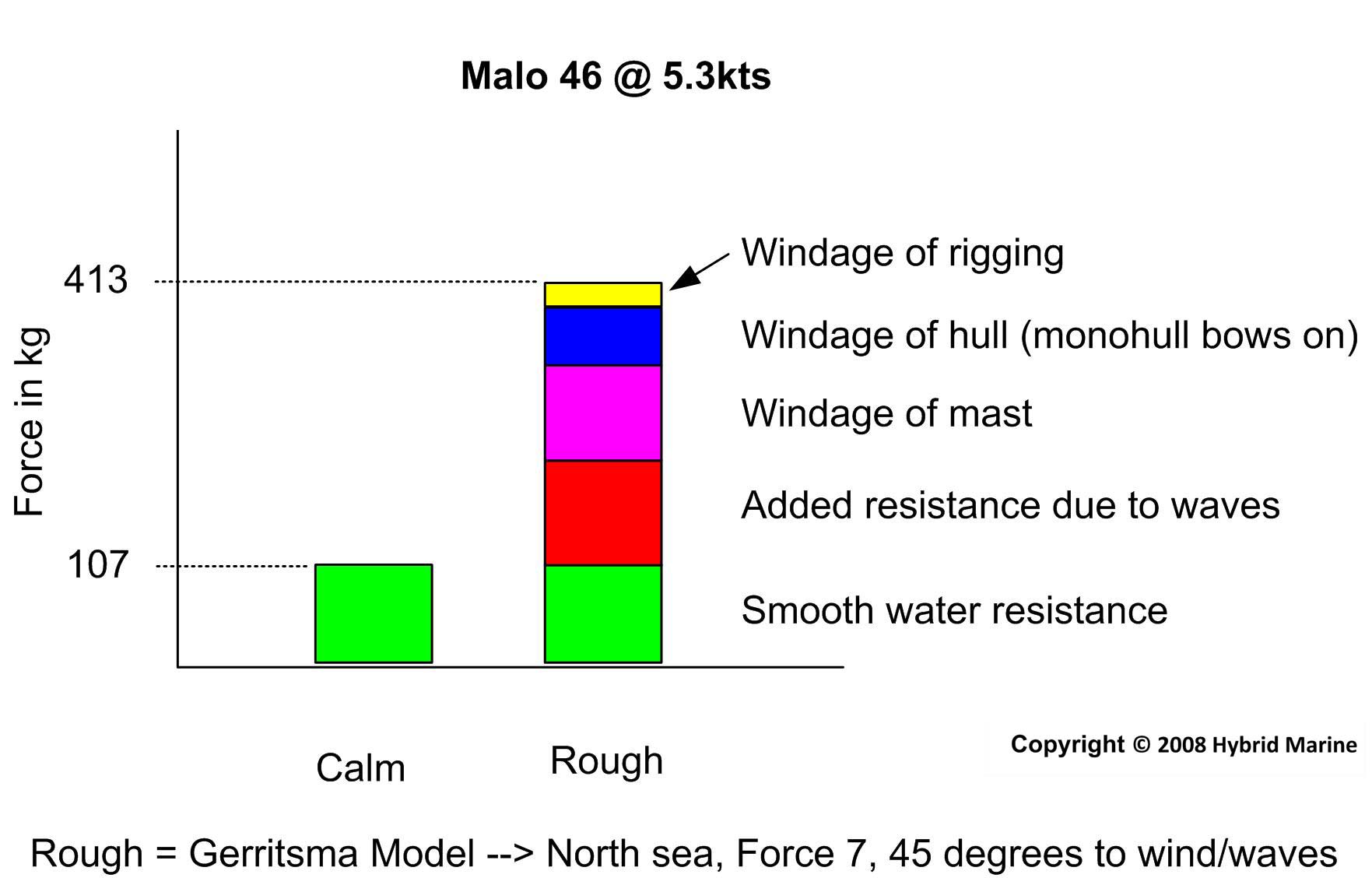

This graph (left) looks at the above vessel at one speed. It can be seen how the extra resistance and windage mount up in rough conditions such that four times the force is required to move at the same speed. While these figures refer to Sailing boats, a similar consideration must be applied to canal boats. The difference between the power needed to push a canal boat along a sheltered canal at 3mph and that needed to make a tidal crossing such as the Ribble link in open water with tidal flows of 3-4mph is considerable. In calm waters, a 60ft narrow boat may need 3-4kW to propel it at 3mph in open water to make headway against a 3-4mph tidal river flow. This may increase to 20-25kW or more. |

Comparison of Systems

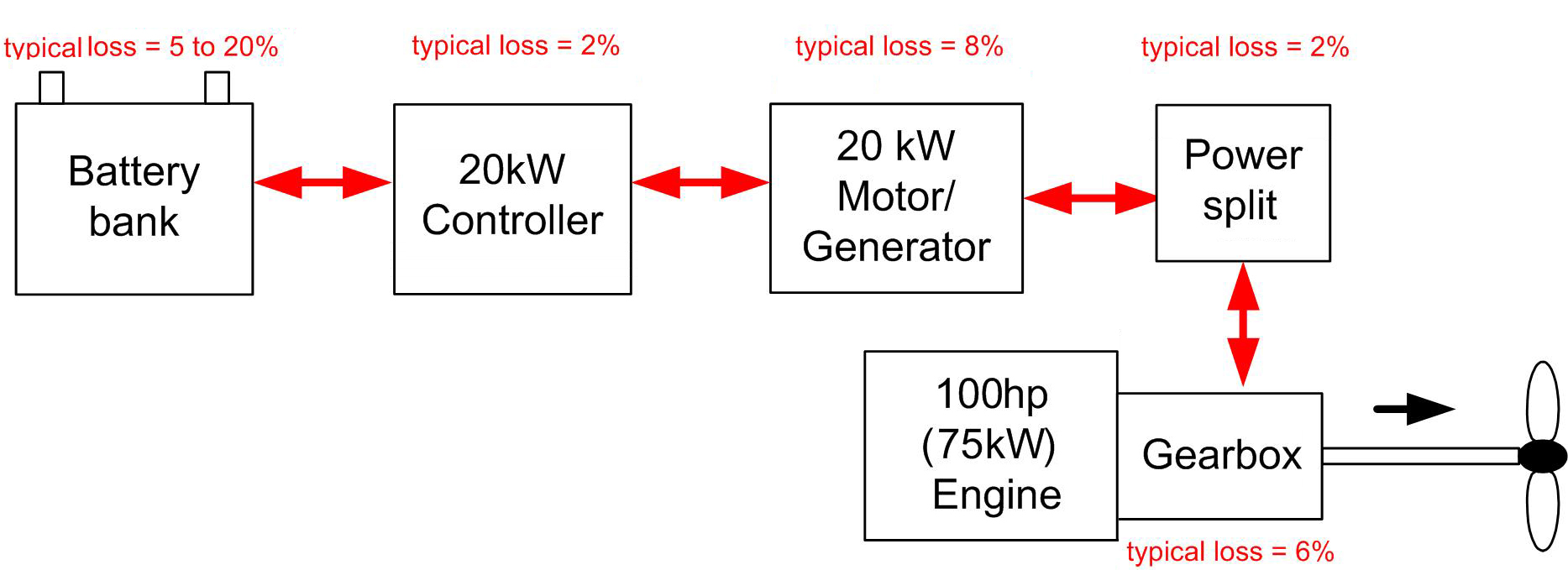

Regarding the examples used in the section, What is a Hybrid? Let us look at how a 100hp conventional diesel could be replaced with a hybrid of similar performance.

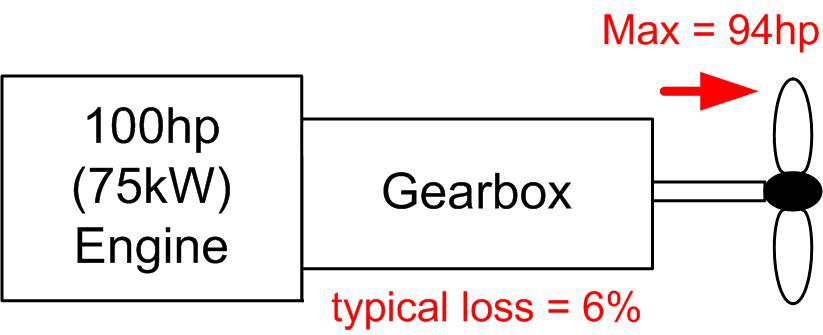

Conventional engine

A 100p engine can supply approximately 94hp to the propeller through a low loss gearbox |

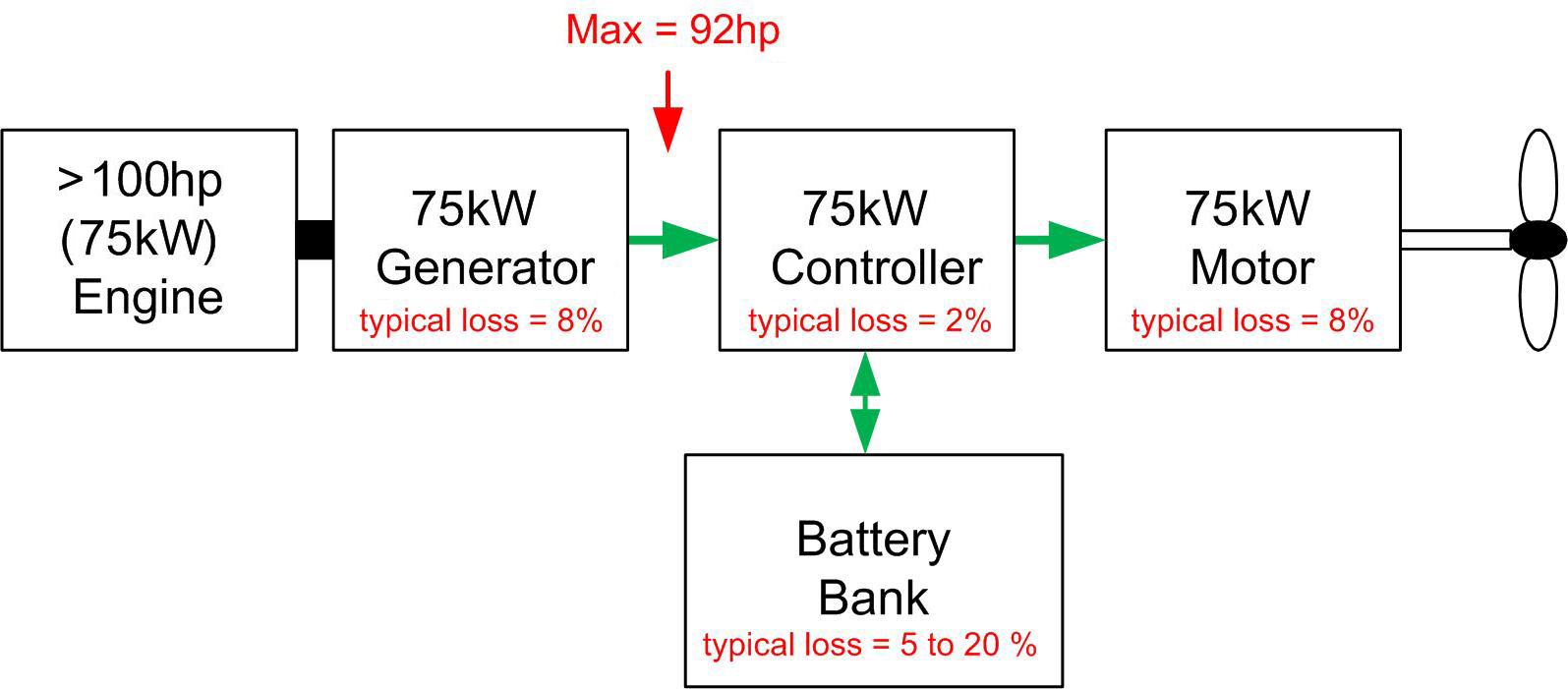

Serial Hybrid

We have eliminated the gearbox for the serial hybrids, but there are more components in the drive chain.

When transmitting power from the engine directly to the propeller, we go through the generator, controller, and motor and incur their associated losses.

To achieve 94hp at the shaft, we need to upsize the engine to 113hp ( 113hp * 92% * 98% * 92% = 94hp).

Parallel Hybrid

Since the parallel hybrid maintains the conventional drive chain of Engine -> Gearbox -> Propeller, the engine can stay the same size as a conventional system. The motor and generator functions can now be combined into one unit. Since the hybrid has little to offer in efficiency improvements at high powers, the motor/generator can be sized for moderate to low power use.

Provides 94hp from the Engine or ~25hp from the Electric drive.

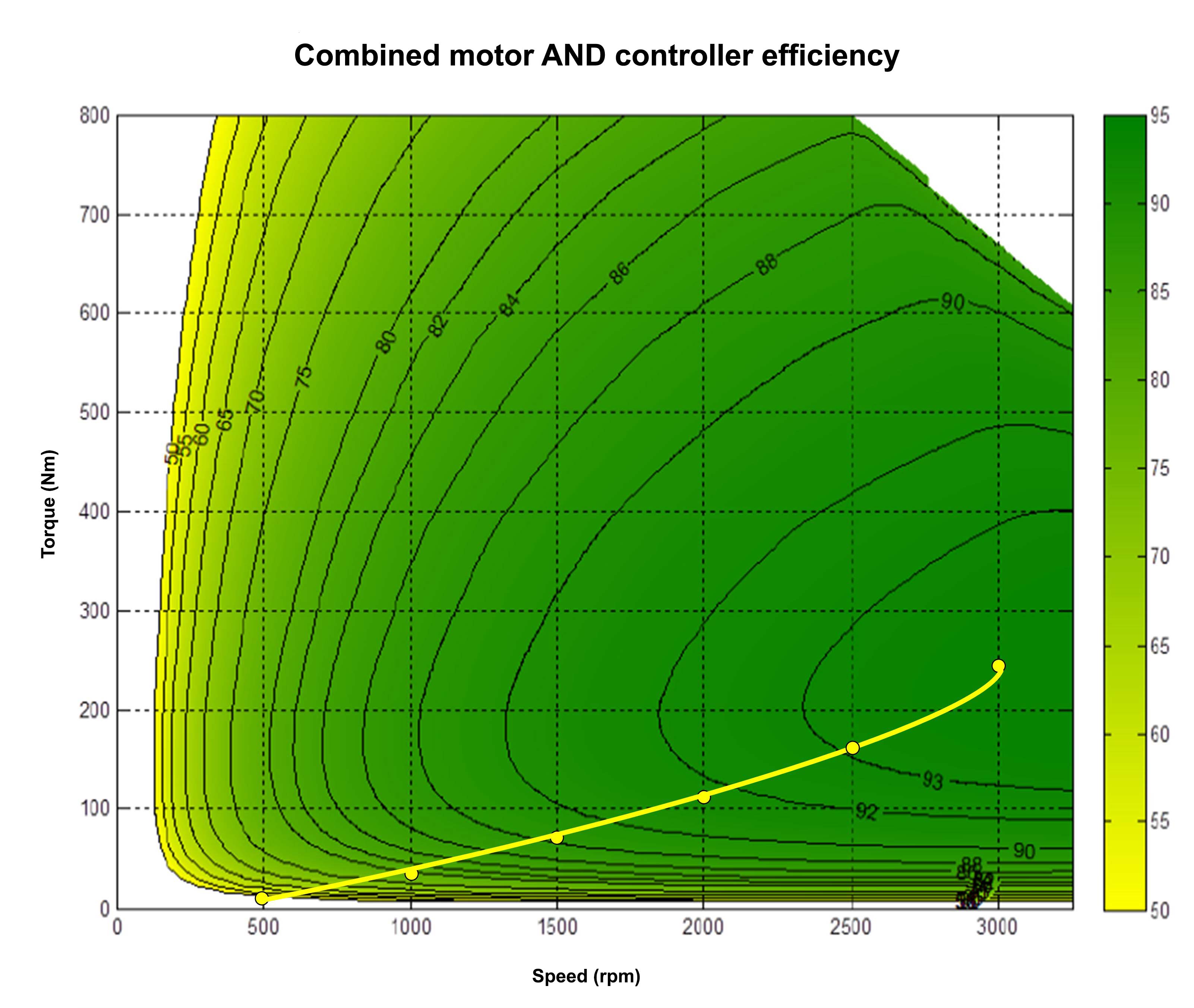

Motor efficiency

The point is that a serial hybrid must size its motor to provide the maximum power requirements. If you operate considerably below maximum power (where hybrid has the most to offer), then motor losses are much higher. In this case, we have gone from a 5% loss at high loads to a 16% loss at low loads. A parallel hybrid provides maximum power with the engine, and the motor is optimised for best efficiency at moderate loads where it will see most of its operation. |

Summary

The table below summarises the comparison between a conventional transmission and the two main hybrid configurations.

Diesel |

Parallel Hybrid |

Serial Hybrid |

|

| Engine Size | 100hp | Same size, 100hp | It needs to be 13% larger at 113hp |

| Efficiency at high power | approx 30% | Same as Diesel | Reduced due to more components (giving greater losses) and a bigger engine |

| Fuel consumption at high power | 0.3L / kWh | Same as Diesel | Increased due to greater losses and bigger engine |

| Efficiency at 1,200 RPM | approx 10% | Better, approx 15% | If the motor is sized for 100hp (75kW), then its efficiency will drop off at low loads. It will struggle to be better than a parallel hybrid. |

| Engine location | Fixed at shaft | Fixed at shaft | More flexible in location as the transmission of power is electrical. Does not need to be located at the shaft. |

| Reliability | Good | Same as Diesel | More components in the drive chain, more points of failure that will disable the operation |

| Redundancy | None |

Electric dive if the engine fails Engine drive if hybrid fails |

Failure of the motor or controller will disable the craft Electric drive if engine/generator fails |

| Cost | Lowest | Adds cost of batteries, mid-size motor/controller | Adds cost of batteries, large generator, large controller and large motor. Highest cost |

This is not an extensive treatment; however, for us at Hybrid Marine, the case is very clear. For small craft with single or dual engines, the Parallel hybrid offers the best solution. Costs are less than an equivalent serial system, performance is better, and redundancy is much improved. It took quite a bit of work to come to this conclusion, we did start with developing a serial hybrid system but the limitations of a Serial configuration became clear so we concentrated on Parallel systems.

Hybrid Marine was the first in the world to introduce a production Parallel hybrid to the market in 2007, and so far, we have not had cause to regret our choice.

Before we compare the merits of Parallel and Serial hybrids, we need to look at motor efficiency. Motors are often specified with a very high performance (efficiencies of 92% to 96% are often quoted). We discussed in the

Before we compare the merits of Parallel and Serial hybrids, we need to look at motor efficiency. Motors are often specified with a very high performance (efficiencies of 92% to 96% are often quoted). We discussed in the